Stephens Belting Co Ltd was asked by another Stephens family member, Mr Ira Stephens, if, due to their experience of working with rawhide material, they could look at making rawhide hammers. Ira Stephens was already making and selling hammers but was not happy with the quality of the rawhide hammers they were currently purchasing. Trials were carried out and the hammers proved a success albeit initial requirements were only 3 sizes and in limited numbers.

All sales of the rawhide hammers initially went through Ira Stephens but it soon became apparent his numbers alone would not be viable to continue manufacturing. It was agreed that Stephens Belting and Birmingham belting could also sell rawhide hammers direct to other customers. Walter Runciman Stephens, who was the son of John Runciman Stephens one of the 4 Stephens brothers was tasked with developing the manufacturing and sales of hammers.

Walter’s first decision was come up with a business name associated with hammers. He decided to name the company after the ancient Norse God of Thunder who owned the most miraculous of hammers, Mjӧlnir, a throwing hammer, which always sped directly to its mark, slew the giant then rebounded straight back to Thor’s hand.

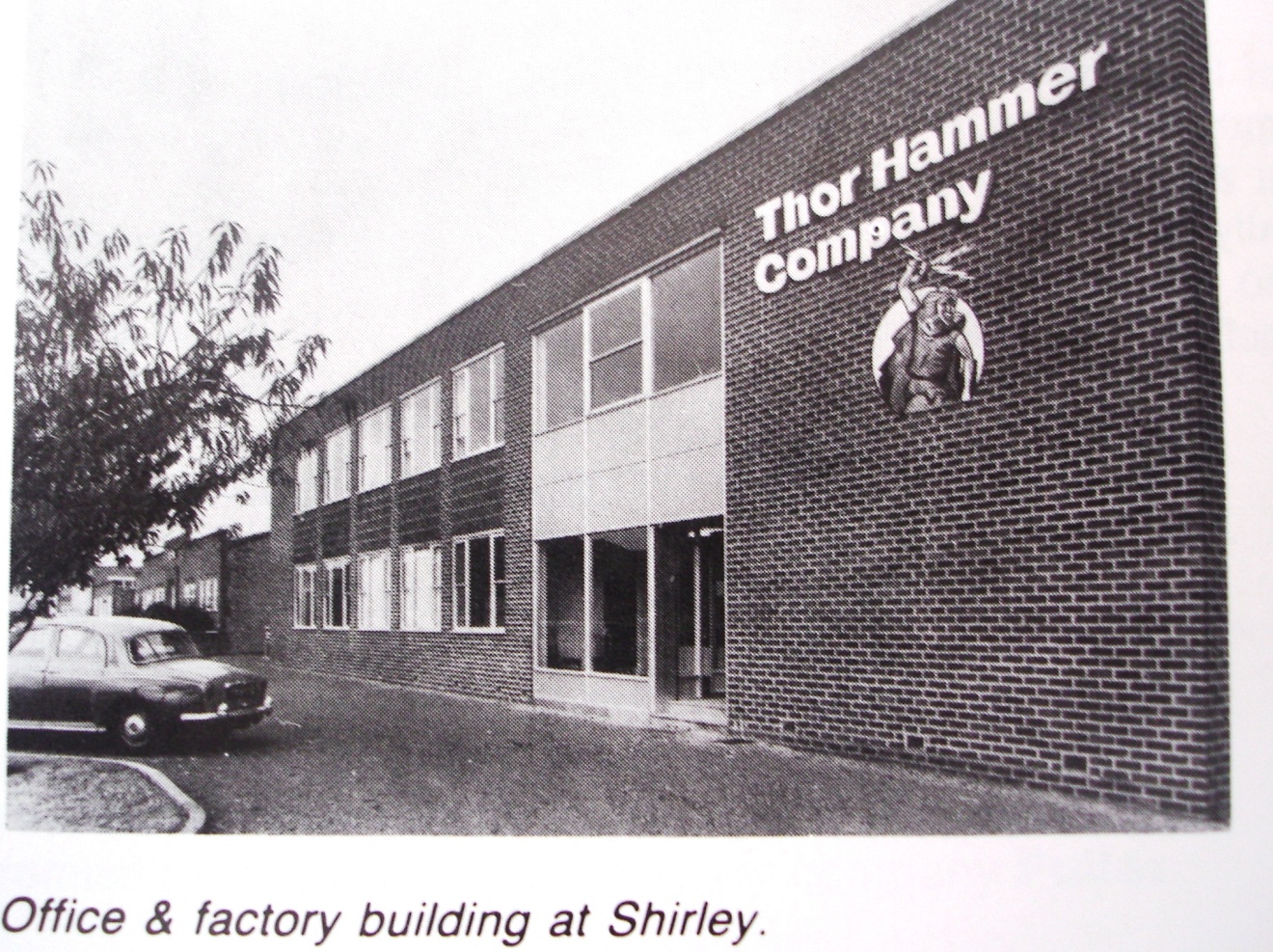

The business name Thor Hammer Company (Proprietors Stephens Belting Co Ltd) was duly registered.

The separation from Stephens Belting meant that Walter could concentrate all his efforts on further developing the company and within a year, new products were already being designed and launched.

One of the most popular items launched around this time was a Copper Rawhide hammer which had an Iron head fitted with a Copper Face at one end and Rawhide Face at the other.

A local car manufacturer was so impressed with the product that they supplied a Copper Rawhide hammer in the toolkit with each car they made.

The hammer was used to tighten and loosen the central wheel nuts or ‘Spinners’ used to secure the wire spoke wheels fitted to most cars at this time.

The car company was S S Cars now known as Jaguar and this type of hammer remains our biggest selling range to this very day.